Pallet wrap recycling: 3 ways to minimise the environmental impact of your warehousing operations

Excellent load stability and safe transportation of your goods is a key focus for every business. We all know how crucial it is for the products to arrive in perfect condition to enhance the customer experience.

Over the last few years, words like sustainability and environmentally friendly have began to appear more and more, with many business striving the become carbon neutral.

Here we’ll explain how to correctly recycle your used stretch film.

What is pallet wrap?

Pallet wrap, commonly known as stretch wrap or stretch film is one of the most well recognised packaging materials on the market today. It is used to secure goods to a pallet and protect them in transit and storage.

Is pallet wrap recyclable?

The short answer is, yes pallet wrap is recyclable, however it isn’t necessarily a simple process. There are a few factors to consider before throwing your waste pallet wrap in the recycling bin.

- What material is used for pallet wrap

Pallet wrap is usually made from LDPE, or low-density polyethylene plastic which is a lightweight and flexible material. - Which plastics cannot be recycled

While there are many different types of plastic that can be recycled, some are more difficult than others and there are plastics that are not recyclable. LDPE plastics can be difficult to recycle, however some recycling facilities accept clean and uncontaminate pallet wrap.

Biodegradable plastics mays sound like a sustainable alternative to traditional plastics, however they can actually cause more harm than good in the recycling process. The plastics can contaminate the recycling stream and usually require specific composting conditions to properly break down. - Choosing a recyclable stretch wrap to protect the environment

There are now options to use pallet wrap made from recyclable materials such as paper, however these can be very costly and not as effective as plastic stretch wrap when it comes to load stability.

To minimise your environmental impact, you should first consider the volume of film being used. Switching to a pre-stretched film will ensure you still have excellent load stability but with much less wrap per pallet.

Using a pallet wrap that contains at least 30% recycled content is better for the environment than using a wrap made entirely from virgin plastics. It is important to consider the end-of-life disposal options for any wrap containing recycled content.

3 ways to minimise the environmental impact of your warehousing operations

There are many ways to make your warehouse operations more environmentally friendly, especially when it comes to packaging. There’s no one size fits all when it comes to packaging and working with a supplier that can assist you with your bespoke packaging needs is so important.

Using efficient, environmentally friendly packaging

Sometimes it’s difficult to avoid plastic, we get it. So that’s why it’s important to be as efficient as possible with your plastic packaging. One of the most effective ways to be more efficient is to reduce the usage. This could be by switching to a stronger pallet wrap and using less of it, or using a thinner, pre-stretched film rather than a thicker conventional wrap.

Paper stretch wraps are now available however these are very costly as not yet as effective as plastic wrap if you’re main objective is load security and pallet stability.

Most protective packaging such as bubble wrap and void fill is available in paper from most packaging distributors worldwide. Generally these work just as well and are great alternatives to plastic packaging.

Recycling any materials possible

Ensuring that you recycle the

plastic packaging you do use goes a long way in reducing the environmental

impact of your warehouse packaging. Ensure the packaging you use is accepted by

the local recycling program and you dispose of it correctly.

Make use of technology

Making use of technology in packaging can help contribute to a sustainable warehouse packaging environment. There are several ways you can utilise packaging technology including automated packaging systems to optimise material usage and reduce waste.

Automatic machines and packaging systems can be used to exactly fit each item, minimising the unnecessary need for excess materials.

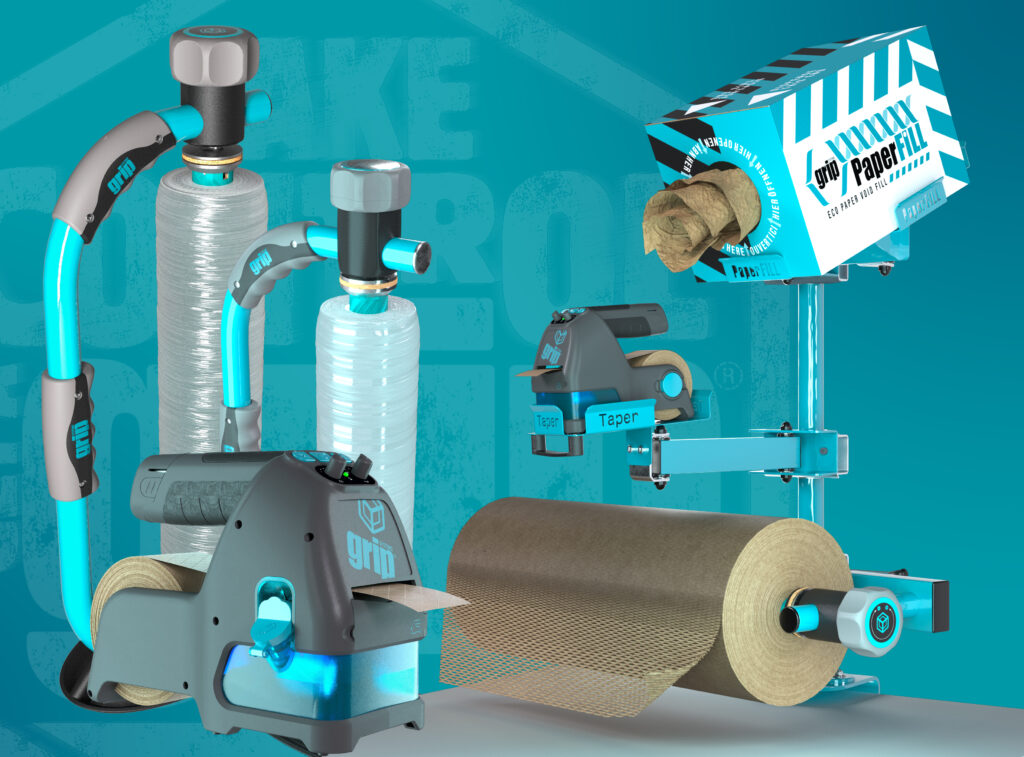

Prevent unnecessary pallet wrap usage with innovative pallet wrap technology and have 40% savings with the Grip Applicator

Specially formulated with a unique blend of polyethylene, Grip Film is high performance pre-stretched film designed to increase the holding force and stability of a pallet whilst using the minimum amount of film possible.

Pre-stretched pallet wrap is a type of stretch film that is commonly used in warehouse operations all over the world. It gets it’s name from the manufacturing process where the film is stretched to almost breaking point. When used in conjunction with the Grip Applicator, here are some benefits you can expect from Grip Film.

- Film optimisation: Grip Film is designed to be stretched to maximum capacity in production, meaning you get exactly the meterage you pay for.

- Consistent and secure wrap: The Grip Applicator ensures a consistent, strong wrap around your pallet with the tension mechanism.

- Reduced film breakage: Pre-stretched film is incredibly puncture and tear resistant.

- Reduced pallet wrap usage: Due to the strength of the film, the need for additional layers of wrap is reduced.

- Waste reduction: As a result of reducing the amount of stretch film needed per pallet and the thin properties of the pre-stretch film, clients notice a significant reduction in waste.

- Cost reduction: Since the system allows operators to use less material, this results in a significant cost saving when compared to conventional pallet wraps

- Easier and faster application: Grip film requires less physical effort to apply, as the film is already pre-stretched and requires no manual stretching from the operator. The erganonic stretch film applicator takes all the strain off the operator, enabling them to wrap the pallet much faster and safer with a very strong and consistent quality.

Pallet wrap recycling in the UK

In the pursuit of a greener future, the UK has been actively promoting more sustainable practices, including the recycling of packaging materials such as pallet wrap. As pallet wrap is a widely used material it’s disposal can contribute to plastic waste and environmental damage if the disposal is not correctly managed.

Dedicated recycling bins and partnerships with waste management companies facilitate the collection of used pallet wrap, ensuring it’s separation from other waste streams. The collected stretch wrap undergoes sorting and processing, where it is transformed into recycled plastic pellets. These materials are repurposed in various plastic products that contain recycled content.

Pallet wrap recycling allows organisations to significantly mitigate the environmental impact of warehouse operations. Embracing these sustainable practices not only aligns with the movement towards a greener future, but also presents opportunities for cost savings and improved efficiencies.

Together, we can achieve a sustainable future without compromise on quality.